The Simple Pump

Part One

By

Cognitive Dissonance

The following is the first of three articles outlining the research, preparation and installation of The Simple Pump, a high quality mechanical pump used both in everyday applications such as a ranch, farm, off grid cabin or homestead, as well as an efficient backup to an existing fresh water pumping system. These are long reads, not brief outlines, and apply only to our specific situation and location. Your experience can and will vary from ours.

It is said we can’t live more than three minutes without air, three days without water and three weeks without food. While I never wish to test any aspect of that statement, prudence dictates we prepare as best we can for those events of greatest probability. Thankfully, running out of (breathable) air is low on the list (at least where we live) while water and food are at the top.

When Mrs. Cog and I began our search for a new home, high on the list of ‘needs’ was a (relatively) remote location with its own well and septic system. We did not wish to rely upon outside sources to supply life sustaining water and/or to remove our waste product. Systems break when stress is applied, be it financial, governmental or personal. It is far easier to maintain our own systems than for the local, state or national government to maintain theirs.

As Mrs. Cog recounted with great humor in a November 2014 article (Amps Times Volts Equals Watts) a discussion about wells and water cropped up when I began to tackle the issue of sustainable solar power. Our well is deep……which is both a good and bad problem depending upon your point of view. Deep usually means a steady supply of fresh water as well as one less likely to be contaminated by surface sources. Deep also means ordinary ‘suction’ hand pumps simply don’t work beyond 20-30 feet. Anything deeper requires the pump be placed in the well rather than above it. There is no getting around this fundamental fact.

Our relatively modern home was built with a pressurized (well) water supply system, meaning the electric submersible pump at the bottom of our 300+ foot deep well pumps water to the surface and into a pressurized water tank in the basement. Any time we open a tap or flush the toilet, water is instantly delivered where needed.

However, our existing water supply depends upon a fully functioning electrical system (in whatever form that takes) in order to supply water. A single point of failure can leave us without water. It does not take a stretch of imagination to create a list of items that might bring our system down, ranging from local (submersible pump failure, generator fuel runs out, solar inverter failure,) to regional/national (electrical grid failure, weather disaster) to natural (sun) or artificial (nuclear weapon) electromagnetic pulse (EMP).

If the electrical grid were to fail, we have installed a whole house generator as a backup. If that were to fail or run out of fuel, my solar panels, batteries and inverter will act as a backup to the backup. There are loads of places that you could get these items from, for example, some people get solar inverters from Solar Man Australia. However, this violates the golden rule regarding backup systems. Your backup should always be lower tech than the original and not the other way around. As you can see I was actually climbing the complexity curve, not descending, thus the need for a hand operated mechanical backup for the fresh water system.

The prudent assess, plan and implement; the preoccupied practice passive hope there will be no change. All others simply give the possibility of disruption little to no thought whatsoever. To each his own; we don’t wish to be judgmental. Mrs Cog and I are simply attempting to walk the talk as best we can.

Research

After a couple of computer sessions reading about mechanical pumps designed to pump from deep wells, a few things became clear. There are a lot of junk pump systems out there ranging from dirt cheap to outrageously expensive. There also are a few quality ones. In addition, nearly everyone presents themselves as an expert, especially those who clearly are not. However, the advantage of reading the so called experts is you get to decipher a boat load of mistakes masquerading as self proclaimed successes.

In a nut shell my pump requirements were simple, though one might argue unreasonable. The system must be installed and operational before the ‘event’ occurs that prompts its use. If this means sitting around for 5-10-20 years with infrequent use other than monthly checks and required maintenance, so be it. And I have no desire to haul water from the pump in five gallon containers each time I want to brush my teeth, flush my toilet or cook a meal. This means the pump must be integrated into my home’s existing fresh water supply system.

Therefore the pump must be engineered from scratch with these goals in mind and not be converted from another primary role to fill a secondary need, then marketed as if it was always intended to be what it had become. While pretty is nice, longevity and function must come first, and the pump must be constructed from high quality materials and components.

My wife and daughter are both petite, which means they cannot apply great mechanical force to operate the pump. Quality engineering with efficient use of leverage, along with tight tolerances during manufacture, are the solution to this problem. As well, they are not mechanically inclined nor should they be. Therefore the operation of the pump must be simple and intuitive; otherwise it becomes an impediment rather than a solution.

The pump and its application must be flexible and able to adapt to my needs as my situation, and financial ability to expand, changes. I eventually wish to add a solar powered motor to the mechanical pump system. This requires a pump system that can be expanded in the field without discarding major components. Of equal importance is the ability to quickly revert back to a simple hand pump if the motor or solar panel power system breaks down. This is easier said than done.

Most importantly the pump must be repairable in the field. A pump is completely useless to me if I must send it back to the manufacturer for repairs. Usually systems break when in use. If I am actually using the hand pump I am in dire straits and cannot afford to lose several weeks to repairs. I need water today and every day after. If I can’t keep the repair components on hand and have the knowledge and ability to repair it, then this is not the pump I seek.

Finally the company producing the pump must be a viable going concern and be responsive to my requests for help and support. These qualities are usually found in small businesses that have developed a niche market and wish to grow using word of mouth references as well as traditional advertising. A company who produces a few products extremely well is more likely to survive than one who is simply a middle man for products manufactured elsewhere. If I can’t work directly with the source of the pump I don’t want it.

Rather quickly I found all these requirements were amply demonstrated in The Simple Pump by Simple Pump Company, LLC. Interestingly, upon discovery I was immediately suspicious of the pump and the company since I considered my requirements demanding and next to impossible to fulfill…..especially considering the third rate competition out there. When you discover a rose growing in a field of weeds you can’t help wondering if what you’re seeing is real.

It was and it is.

The Simple Pump

Cost is always a factor in any decision we make. I assessed correctly that quality would not come cheap, nor should it. If a company can’t make a decent profit on their product, they won’t be around very long, thereby circumventing my need for the pump company to still be in business many years down the line. While the pump was not cheap, neither was it expensive. It provides good value for my money and I will speak further on this subject later.

Well Preparation and Ordering

The initial well preparation work, as well as the Simple Pump ordering, was done back in December of 2014 with the intention our installing it during the following summer. Unfortunately life got in the way and the actual installation is only now being completed.

I contacted a representative of Simple PUMP Company, LLC via the “Get a Quote” page on their website by filling out the requested information. The representative emailed me back within 24 hours and we began a back and forth verbal and email conversation as we worked out the details of my specific situation.

The online questionnaire is comprehensive and answering the questions properly is extremely important if you wish to purchase a system designed for your actual needs. I suspect many will find they need to actually examine their well, including pulling the submersible pump (assuming you have one) up and out of its casing, in order to properly answer the questions. This was exactly what happened to me. And as it turned out, if I had not pulled the submersible pump to inspect and measure I would have run into significant problems later on.

The first question on the list asks for the water level of your well, also referred to as the ‘static’ water level. I had no idea what that depth was for my well, only the drilled depth of the well which was the second question. Further down you are asked about a submersible pump and its depth. To those who know nothing about wells and water, this is all Greek.

When a (water) well is installed, or ‘drilled’, the well driller begins the process by drilling a borehole and installing a metal or PVC casing. The casing acts as a conduit for the drilling/pumping system while holding back loose rock and dirt/gravel from collapsing or filling the well. In theory the borehole is drilled to bedrock, and then the casing is seated into the bedrock before the remainder of the well is drilled.

Using a combination of drilling experience and expertise, the professional driller continues the process of drilling ever deeper until either water is found in a quantity sufficient to support a household or you run out of money drilling dry holes.

Depending upon conditions while drilling, the operator might decide to drill the hole (much) deeper than the level s/he first hits water. For example……the recovery rate of the well, the rate in gallons per minute in which ground water flows back into the well during/after pumping, might be much less than the pump is capable of removing from the well when the household is using water heavily. The extra depth of the submersible pump below the static water level affords a buffer, a column of water in the well above the pump which is drawn down during heavy use, then replenished more slowly by natural water flow back into the well.

Suffice to say the drilled depth of the well might be much deeper than the actual level of water in the well, the so called static water level. And the depth where the submersible well is placed will be somewhere between the static water level and the bottom of the drilled well.

In my case I attempted to measure the static water level by pulling the well casing cap to the side and dropping a weighted line down the shaft. No such luck though because at around 75 feet I hit an obstruction what was later determined to be a torque arrestor, essentially a rubber bladder placed at regular intervals along the well water discharge pipe to keep the submersible pump and pipe centered in the well casing and to help prevent the pump and pipe from spinning too much when the pump starts up.

A simple pump.......but not The Simple Pump

I decided to get a professional involved at this point since the well was originally drilled over 325 feet deep and I did not have the equipment or the expertise to pull the heavy weight of pump and pipe out of the well. A few questions asked around the area yielded the phone number of the guy who had actually replaced the submersible pump at our place a few years before we bought it. He arrived a few days later and we proceeded to pull the discharge pipe and pump.

By the way, before pulling up the submersible pump, you need to carefully consider where you are going to lay out all that discharge pipe and electric wire. If it is a deep well, the professional may actually rope the discharge pipe to a truck and use a tripod and wheel assembly to pull all that weight up the well. Remember, it’s not just the pipe and pump you are dealing with, but also the weight of the water in the pipe. You’re going to need plenty of room both to maneuver the truck and lay out the pipe.

We discovered several things which convinced me the money spent on the professional was well worth the cost. The submersible pump had originally been set at slightly less than 300 feet. But after pulling up the pump we both noticed the actual pump had thick silt on the bottom half and the last 10 feet of pipe was also dirty. The pro explained that the pump was sitting in the silt at the bottom of the well and we should raise it at least 25 feet, something we immediately did. This explained why I was changing my filthy well water filter every 6 months.

We also removed the torque arrestor at the 75 foot level to clear the way for the simple pump installation. If I can’t drop a line past the torque arrestor I certainly can’t get the separate Simple Pump discharge pipe down there. The next torque arrestor was at 160 feet, which we left in place because it wouldn’t impede the Simple Pump.

The next step was to measure the static water level which indicated at 98 feet. Please note that this static water level changes all the time, day to day, week to week, season to season, lower after heavy use and higher when away on vacation. This is especially so if your well has a poor recovery rate (explained elsewhere) or you are watering the garden during a drought.

I measured the static water level again a year after the first measurement and found the level had risen 20 feet. Pay attention to your water use before you conduct a measurement. Based upon my experience I would take the measurement immediately after you finished your normal heavy use, usually after everyone has showered, the dishes are washed etc. Then I would measure again after several hours of low or no water use.

The reason for this is simple. The actual pump at the bottom of the discharge pipe for the Simple Pump is placed well below the static water level to give the Simple Pump a buffer while pumping. You want enough water above the pump to assure proper operation; therefore you want a good picture of the differing static water levels so you never find the Simple Pump sucking air instead of water, a situation which will quickly destroy the pump itself at the bottom.

Back to measuring the static water level. You would be surprised how easy it is to hear the splash from the weight tied to the end of the line when it hits the water, even when you are lowering it slowly. The casing acts like a physician’s stethoscope and transmits the sound all the way to the top quite clearly. Just feed the line down the well until you hit water, then pull it back up a little and let it down several times to establish the exact moment it hits the water. Once you have the correct point, tie a little knot in the string at the top of the casing to mark the length and then pull the line back up and measure it.

At this point we turned to modifying the submersible pump discharge pipe where it exits the casing. I was born and raised in New England, where the winters are somewhat colder than down here in Southwestern VA. The frost line in southern New England is 42” below the surface, meaning if you don’t want something to freeze, it must be buried at least 42” below the surface. The further north you go, the deeper the frost line.

Obviously you don’t want your water line to freeze, so you bury it below the frost line. Where I now live the frost line is 18” and many people around here don’t go much deeper than 12”. The problem I had was the discharge pipe came up and out the well cap, then turned back down into the ground and towards my house. Thus a portion of the water pipe was exposed to the elements and could easily freeze during the winter.

Above you can see the large concrete shell with insulation in the back ground that covered the well casing, to the right the device used to help pull the submersible pump and pipe out of the well, and at left center the well casing with the black water pipe coming up out of the well cap and back into the ground. The yellow wire is the disconnected power cable to the pump.

The way this problem is ‘solved’ around here is to surround the well casing above ground with a concrete casing approximately three feet in diameter and two feet tall. It is capped with a concrete cover and the inside is stuffed with insulation to prevent pipe freezing. Since the ground below the surface, and therefore the well itself, is always around 50° F, the theory is that as long as the winter cold is kept away from the pipe with insulation, the ‘warmth’ from the ground will keep the pipe from freezing.

The problem is the Simple Pump head and handle are permanently attached to the top of a new well cap (to secure the pump you can remove the handle and store it elsewhere) thereby exposing the top of the casing, the well cap and the submersible pump discharge pipe to the cold weather.

While this won’t bother the Simple Pump head (when you stop pumping, the water recedes back down the Simple Pump discharge pipe far enough to prevent freezing) either I needed to come up with some kind of heated ‘pump house’ surrounding the entire installation, which brings its own set of intractable problems, or I relocate the discharge pipe through the side of the well casing below ground and out of harm’s way.

The Pitless Adapter installed in the side of the casing with the pipe to the house attached.

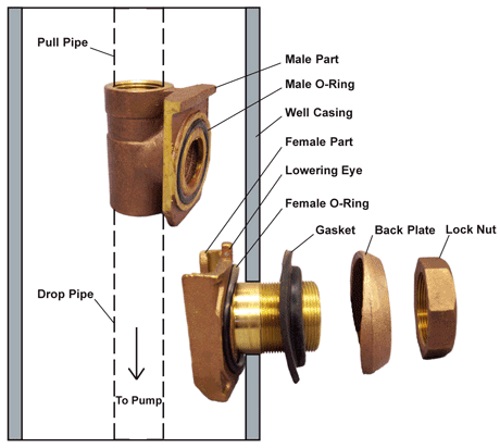

This relocation is accomplished using a Pitless Adaptor, a solid brass fitting consisting of two parts. The Female portion is inserted from the inside of the casing through a hole drilled in the side of the well casing at the proper depth and then connected to the water pipe running to the house. The Male part, which is connected to the submersible pump discharge pipe and mates with the Female part, sends the water pumped up from the bottom through the side of the casing, under the ground, and on into the house.

Essentially the discharge pipe and submersible pump are attached to the Male and then hung on the Female part, which supports all that weight on the side of the casing. See the illustration below. The electrical cable running power down to the pump still exits up through the well cap, then back down into the ground to meet up with the pipe running to the house. This is what we installed while we had the submersible pump out of the well.

Not only was the submersible pump water pipe now fully protected from freezing, but doing so greatly simplified the installation of the Simple Pump later on. If I had not installed a Pitless adaptor to reroute the submersible discharge pipe now, when I installed the Simple Pump later I would have had to deal with the extremely heavy submersible pipe and pump while also juggling the Simple Pump pipe’s weight.

The golden rule of backups states the backup solution should be lower tech and complexity from beginning to end than what it is backing up. It makes no sense to increase the likelihood of freezing my ‘normal’ fresh water supply by removing the well cap insulation just to provide a backup system. However, increasing the security of my primary fresh water supply by installing a Pitless adapter, while also providing an integrated low tech backup system was well worth the additional time and cost and obvious when considered from a big picture point of view.

The fresh water supply in your home is pressurized. If you are attached to a municipal water system, that system provides the pressure for your home water system. For those of us providing our own utilities, the submersible pump pushes water into a water tank, usually located in your basement or utility closet, which holds the water under pressure. This provides the force to propel the water out when you turn your faucet on.

When the water pressure drops below a certain point, the submersible pump kicks back on and pumps more water into the tank, re-pressurizing the system. If designed and calibrated correctly, you never notice much variation in water pressure or flow. So many of us take our plumbing and electrical systems for granted and don’t recognize the fundamental sophistication and complexity of them until they break.

In its most basic form the mechanical Simple Pump pumps water up the well inside its own discharge pipe and out a nozzle on the side of the stainless steel head. Either you place a bucket under the spout, fill it and walk it inside or you hook a potable water hose to the spout and connect the other end to an outside faucet (one that does not have an anti siphon head) or directly to the pressurized tank in the basement.

This way you can hand pump water directly from the well into your existing plumbing system. There is a water pressure gauge and check value supplied with the Simple Pump that is installed on the outlet nozzle to help prevent you from over pressurizing the basement tank and/or siphoning water back down the well.

The weak link in this system is that it is not winter tolerant for those who experience freezing temperatures. Once you are done pumping water you must disconnect and roll up the hose, otherwise it will freeze and put you out of commission.

One solution is to route the Simple Pump water through its own Pitless Adapter and out the side of the well casing below the ground, then connect it into the existing water pipe headed to the house. By placing a check value on both the Simple Pump line and the submersible pump line before they join underground at the pipe headed for the house, we can prevent either water system from back washing into the other when operating. Since both discharges are now buried under the ground, there is no concern about freezing. This is the direction I decided to take.

The one downside to this path is there’s no way to install a freeze proof pressure gauge at the Simple Pump to monitor the Simple Pump pressure headed to the basement water tank. When I spoke to the CEO of Simple Pump about this he responded that with practice one will develop a ‘feel’ for when the inside tank has been properly pressurized and you must stop hand pumping. Fair enough. There are never perfect solutions to complex problems, only tough compromises.

Stay tuned for Chapter Two.

12-30-2015

Cognitive Dissonance

This is pure gold. Looking at irrigation for a market garden currently. Really helpful :)

Tenma13

More to come real soon.

Also….I purchased “The Market Gardner” for Mrs. Cog and she absolutely loves it. She’s already hitting me up for a $200 broadfork. Sorry, but I’m presently working on a $5,000 ‘barn’. :-)

Cognitive Dissonance